iXyber APC Optimizer

The Global Dynamic Optimization System (GDOS, RTO). It is designed to unify, at the upper management level, control applications such as multi-parameter controllers (MPC) and other optimizers of the APC, with the aim of solving a common optimization problem while considering all constraints of the subordinate control applications

What's this for

As a production dispatcher, I want to have a tool for directly setting the target indicators and optimizing the entire production scale

As a Production Director, I want to optimize all installations based on a global criterion to achieve the planned production targets

iXyber APC Optimizer - is a global dynamic optimization system for technological processes (GDOS, optimizer). It integrates multiple multi-parameter controllers (MPC) and other subordinate optimizers to set and solve a unified optimization task for technological processes at the entire production scale, considering all constraints

Key advantages

-

Global dynamic optimizer at the enterprise scale, considering local constraints on technological facilities;

-

Automatic reading of subordinate controller configurations for iXyber APC, Honeywell APC, Yokogawa PACE. Automatic connection to applications based on iXyber APC, Honeywell APC, Yokogawa PACE;

-

Communication with lower/higher-level applications via OPC DA, OPC UA, Web API;

-

End-to-end simulation of the optimizer's operation, considering the simulation of subordinate applications;

-

Deployment at the L3 level, with reliability and security of operation comparable to the L2 level.

Integration of subordinate applications

The optimizer consolidates subordinate applications: multi-parameter controllers, other optimizers, and similar systems

How does it work?

During the configuration stage:

- Creating the structure of optimizer variables;

- Linking (mapping) optimizer variables with variables of subordinate applications;

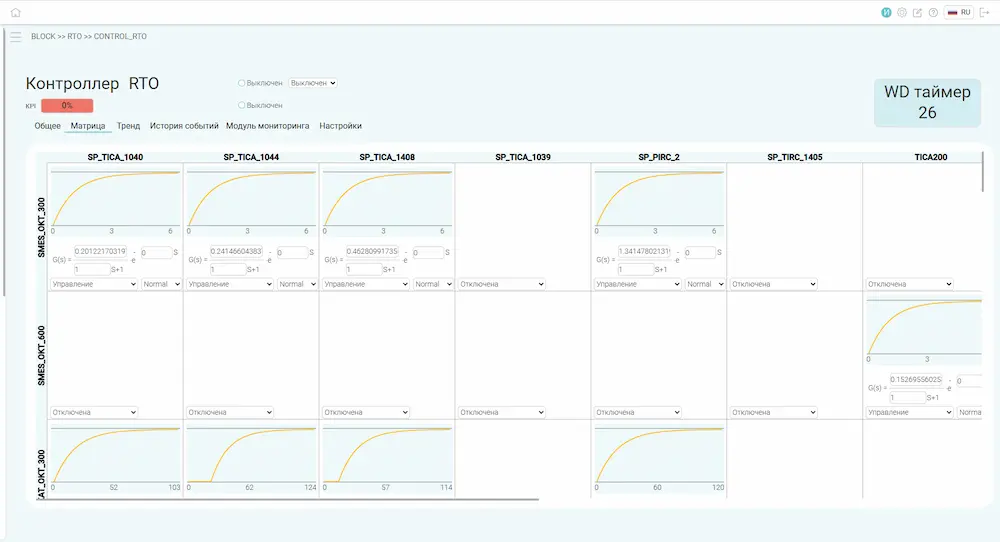

- All model matrices of subordinate applications are combined into a single optimizer model matrix;

- Configuring the global optimization function;

- Binding variables to data sources — for iXyber APC, Honeywell APC applications, this is done automatically.

During the execution stage:

- All current values, constraints, and modes of subordinate application variables are read into the optimizer;

- The optimizer calculates the optimal mode based on the specified optimization function, considering constraints for all subordinate application variables. It then outputs the calculated values as commands to subordinate applications.

GDOS Architecture

Integration of various enterprise components, ensuring coordinated operation of all elements and enhancing management efficiency through automation.

-

Hybrid

The optimizer can manage not only multi-parameter controllers but also other optimizers. -

Multi-level

Multiple hybrid levels of management are possible (multi-parameter controller + optimizers).The number of hierarchy levels is unlimited.

-

Communication with subordinate applications is implemented via OPC UA, OPC DA protocols;

-

Subordinate applications can be developed using software from any vendor. Proven on iXyber APC, Honeywell APC, Yokogawa PACE;

-

Automatic reading of configuration from subordinate controllers implemented on iXyber APC, Honeywell APC, Yokogawa PACE.

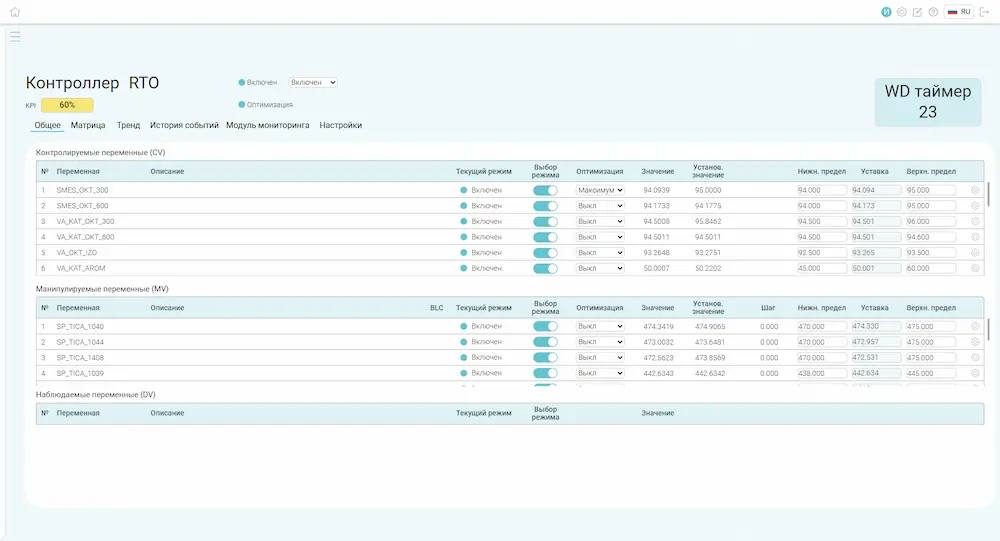

Configuration and Management

Modification of set parameters, operational settings, and modes of the optimizer and its variables; configuration and control of the global optimization mode.

For user convenience, the interface is similar to that of a multi-parameter controller in the iXyber APC Runner environment.

- Enable / disable the controller and variables

- Configure optimization settings

- Set parameters for the controller and variables

- Define lower and upper limits, and assignments for variables

- Set step limits

- Assign variable criticality levels

- Edit transfer function coefficients

- Change the mode of the transfer function component

(forecasting / control)

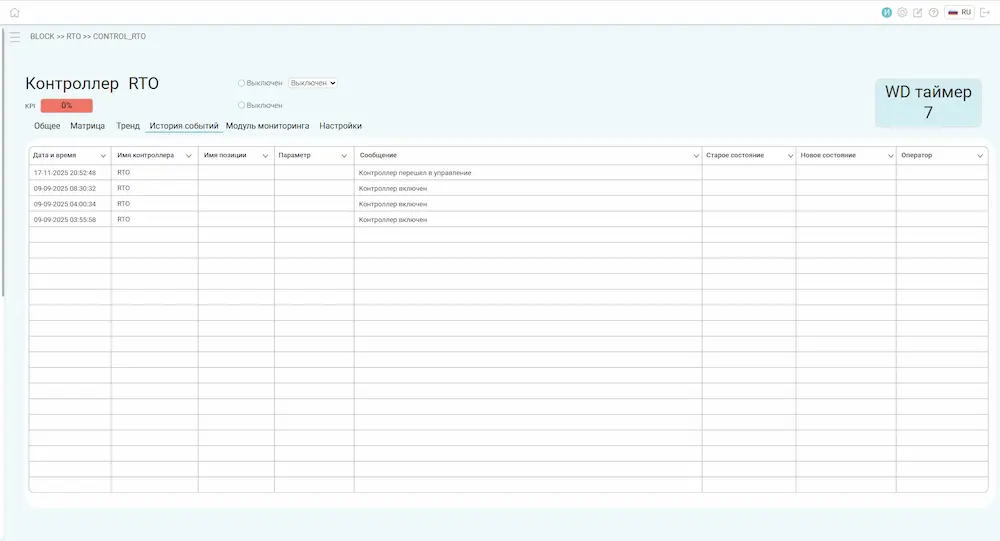

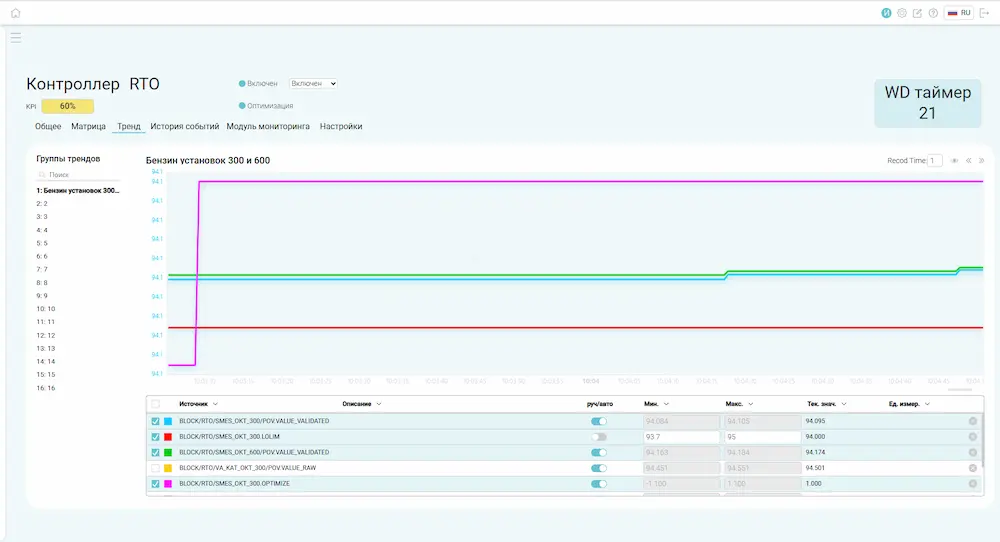

Monitoring

Monitoring the optimizer's operation allows tracking all optimizer events, evaluating parameter changes over time, and calculating performance indicators of the GDOS system.

For user convenience, the interface is similar to that of a multi-parameter controller in the iXyber APC Runner environment.

-

Trends and user-defined trend groups;

-

Occurrence history:

-

parameter changes by users;

-

internal events of computational applications;

-

Export of historical data based on templates.

-

Trends and user-defined trend groups;

-

Occurrence history:

-

parameter changes by users;

-

internal events of computational applications;

-

Export of historical data based on templates.

Simulation

The simulation mode allows autonomous testing of the optimizer, considering the simulation of subordinate applications across the entire hierarchy.

-

Configuration of optimizer parameters, display and editing of values

-

Monitoring and configuring individual variables;

-

Monitoring and managing the simulation over time;

-

Trends and event history of the simulator.