iXyber APC Designer

Comprehensive processing of large volumes of historical technological data, identification of mathematical models, and development of system configurations for advanced process control (APC)

What's this for

As an engineer specializing in advanced process control systems (APC) within a distributed project team, I want to collaborate with my colleagues on a single APC project throughout all stages of its lifecycle, track the history of changes, and have the ability to revert to previous versions

As an expert in the plant's advanced process control system (APC), I want to have access to the APC project to oversee the work on its creation and subsequent technical support. I also want to be able to work with the APC project of any installation within a unified information environment

iXyber APC Designer - is an engineering environment for advanced process control systems (APC) across all stages of the lifecycle: TEA, development, implementation, maintenance, and modernization, with support for team-based distributed collaboration.

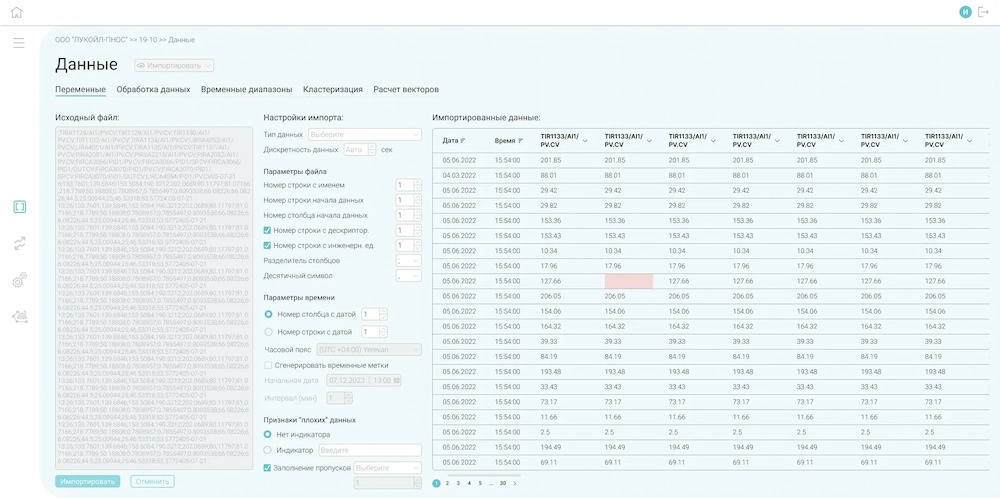

Processing of uploaded data

-

Deletion and filtering of data according to user-defined rules;

-

Filling in missing data (interpolation, constant, mean value);

-

Time shift of data by an arbitrary number of minutes;

-

Outlier removal based on 'n sigma';

-

Smoothing — moving average over n minutes and/or Kalman filter;

-

Cluster analysis for n variables with graphical visualization of the clustering results and a list of identified clusters for subsequent data labeling.

Uploaded data can be viewed in various modes (charts, table), including real-time mode

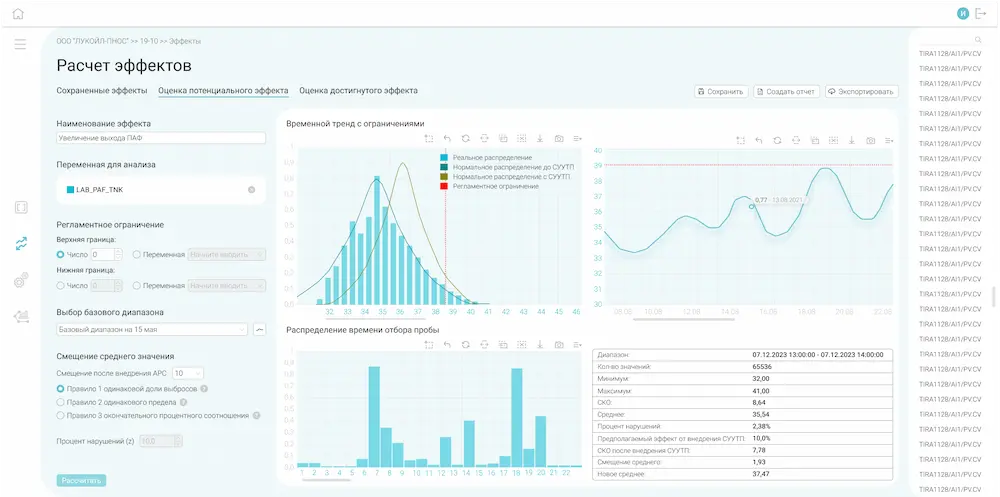

Uploaded data can be viewed in various modes (charts, table), including real-time mode Effect assessment

Evaluation of effects at the stage of technical and economic justification and based on the results of APC system implementation

Approaches to effect assessment vary depending on the type of variable constraint:

-

«Equal limit rule»;

variable without strict constraints or entirely unconstrained -

«Equal outlier proportion rule»;

Variable with strict constraints, where the number of constraint violations is acceptable -

«Final percentage ratio rule»;

A variable with strict constraints, where the number of constraint violations is unacceptablee

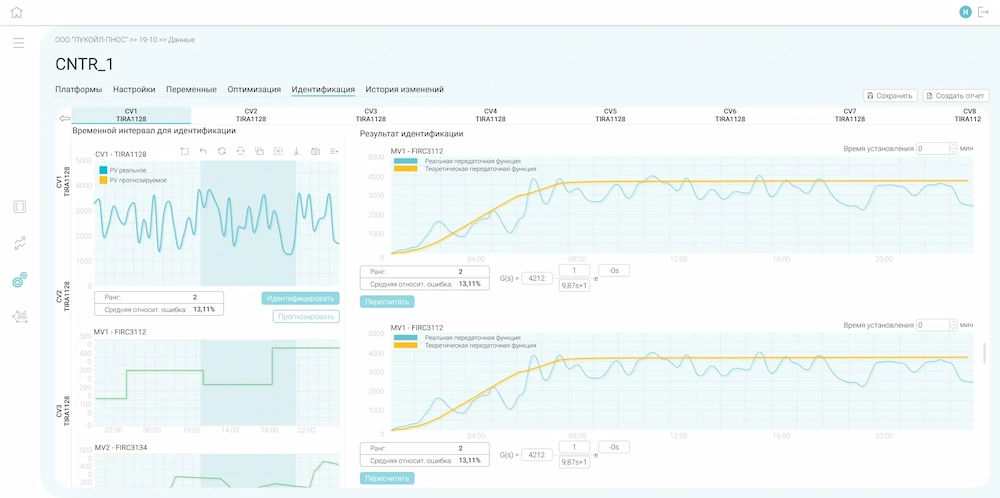

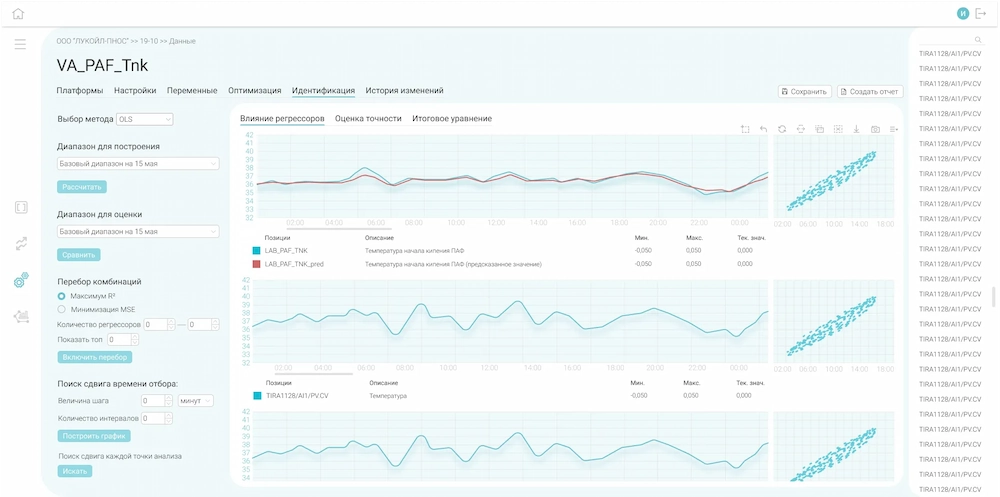

Identification

Identification of dynamic models

Development of dynamic models for multivariable controllers required for precise regulation of complex technological processes.

-

History of changes stored with the ability to switch between saved versions;

-

Ability to modify the equation of the approximating transfer function;

-

Self-documentation based on identification results and the developed APC controller platform, with the generation of a document in MS Word format.

Identification of regression models

Creation of virtual analyzers that enable modeling of equipment operation and real-time analysis of key product quality indicators.

-

Advisor algorithm for selecting regressors (automatic regressor selection);

-

Ability to select the time interval for identification and the time interval for validation of the obtained equation;

-

Marking of 'bad' time intervals;

-

Search for data shift and/or delay in regressors.

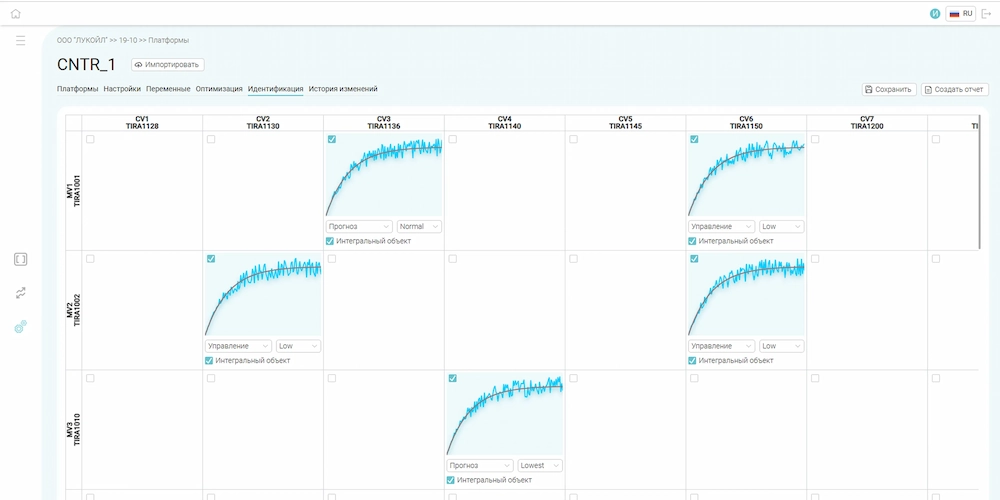

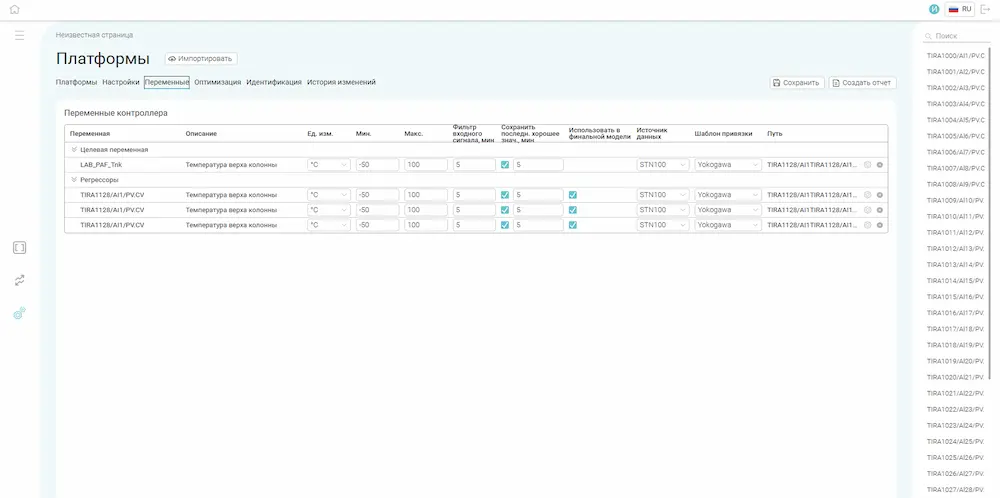

Configuration of computing platforms

Configuration and optimization of the computing infrastructure architecture for the efficient operation of MPC and VA models within the iXyber APC Runner environment

-

Control of versions;

-

Sufficient configurations for rapid design;

-

Flexibility in the structure of the controller and virtual analyzers;

-

Binding templates;

-

Ability to add functionality upon the customer's request.